Quality Assurance in PCB Assembly: Why It Matters More Than Ever

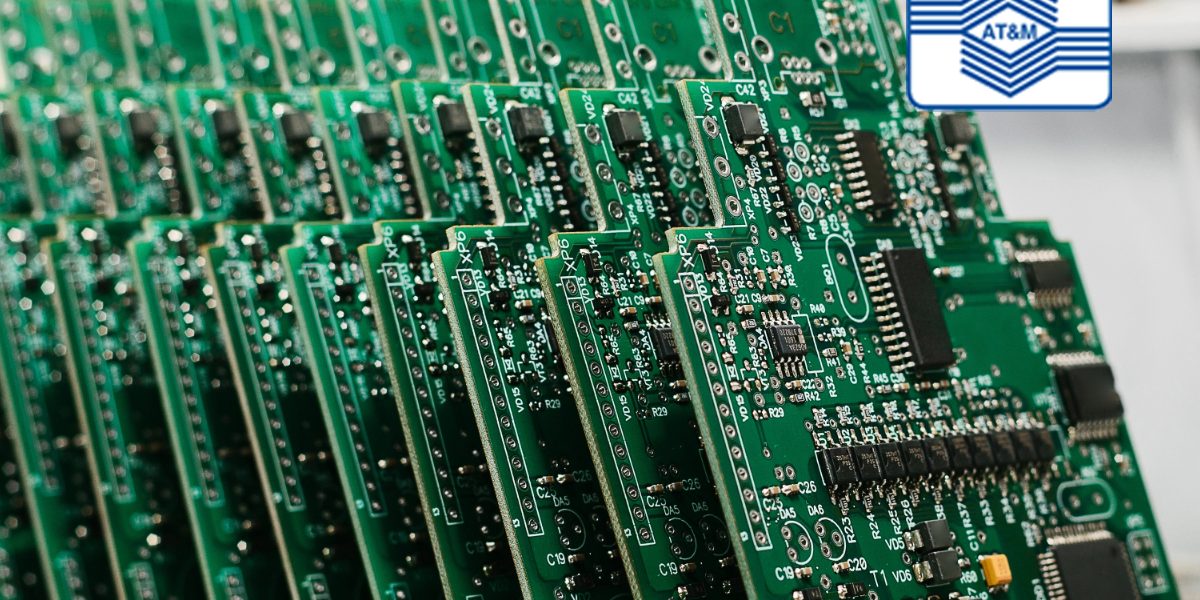

Quality assurance (QA) is a fundamental pillar in printed circuit board (PCB) assembly, playing a critical role in ensuring product reliability, safety, and overall customer satisfaction. With the complexity and integration of modern electronic systems constantly increasing, rigorous QA procedures have become more essential than ever. At AT&M, quality assurance is central to every step of the PCB assembly process, reflecting our commitment to delivering exceptional reliability and performance.

Why Quality Assurance is Critical in PCB Assembly

In industries like aerospace, automotive, healthcare, telecommunications, and mining, even minor PCB defects can lead to costly failures, downtime, and safety hazards. Quality assurance prevents these issues by detecting and addressing defects early in the assembly process, ensuring every board meets strict performance criteria.

Key Benefits of Strong Quality Assurance:

- Enhanced product reliability and longevity

- Reduced manufacturing defects and associated costs

- Compliance with international quality and safety standards

- Improved customer trust and brand reputation

The Importance of Quality Standards in PCB Manufacturing

The adoption of internationally recognized quality standards, such as ISO 9001, ISO 13485 for medical devices, and IPC-A-610, is integral to PCB manufacturing. These standards guide manufacturers in creating consistent, reliable products, reducing risk, and enhancing performance.

At AT&M, our adherence to ISO 9001 and IPC standards ensures our PCB assemblies consistently achieve high-quality outcomes that align with global benchmarks.

Explore AT&M’s Commitment to Quality Standards

Stages of Quality Assurance in PCB Assembly

1. Component Sourcing and Verification

Quality assurance begins long before assembly. At AT&M, components are sourced from reputable suppliers. Rigorous incoming inspections verify component authenticity, performance specifications, and compliance with environmental standards such as RoHS.

2. PCB Design Review

An initial design review ensures the manufacturability of PCBs, identifying potential issues before production starts. This stage helps avoid costly redesigns and ensures optimal board performance and reliability.

3. Automated Inspection Processes

Automated inspection technologies such as Automated Optical Inspection (AOI) are critical in identifying defects invisible to the human eye. AOI systems quickly detect soldering defects, incorrect component placements, missing components, and other irregularities, ensuring every PCB is error-free.

4. Manual Inspection and Functional Testing

Following automated inspection, skilled technicians conduct manual inspections and rigorous functional testing, verifying each PCB meets specific electrical and performance criteria. Functional testing assesses the PCB’s operation under real-world conditions, simulating typical usage scenarios to ensure robust reliability.

Discover How AT&M’s Testing Processes Ensure PCB Reliability

Traceability and Documentation

Traceability is essential for quality assurance, providing complete visibility and accountability throughout the manufacturing process. At AT&M, meticulous record-keeping ensures every component, process step, and quality check is documented. This traceability is invaluable for ongoing quality improvement, regulatory compliance, and addressing any potential issues swiftly and effectively.

Industry-Specific Quality Assurance Requirements

Different industries have unique quality assurance requirements due to varying operating conditions and regulatory standards:

- Aerospace: Requires stringent testing and certification to withstand extreme environmental conditions.

- Automotive: Demands rigorous standards, especially concerning durability, reliability, and safety.

- Healthcare: PCB assemblies must meet strict medical device regulations for patient safety and device efficacy.

- Mining and Industrial Applications: Require rugged, durable PCBs capable of reliable performance under harsh conditions.

AT&M excels in providing specialized quality assurance processes tailored to these specific industry requirements.

See Why Industries Trust AT&M for Quality

Continuous Improvement and Staff Training

Quality assurance is not a one-time effort but an ongoing commitment. AT&M continually invests in staff training and process improvement initiatives, ensuring our quality assurance practices evolve with technological advancements and industry changes. Regular training programs keep staff updated on the latest quality standards, inspection techniques, and regulatory requirements.

Sustainability and Environmental Responsibility

Sustainability and environmental compliance also form essential aspects of quality assurance. RoHS compliance, which restrict the use of hazardous materials, are fundamental components of AT&M’s quality framework. By prioritizing sustainable practices, we ensure our PCB assemblies are environmentally responsible and safe for global markets.

Learn About AT&M’s Sustainable PCB Assembly

Conclusion

In today’s competitive market, where reliability, safety, and performance are paramount, quality assurance in PCB assembly matters more than ever. Through robust inspection procedures, rigorous testing protocols, adherence to international standards, and continual improvement initiatives, AT&M sets a benchmark in PCB manufacturing quality.

Partnering with AT&M ensures not only industry-leading PCB quality but also peace of mind, knowing your products are reliably built, meticulously tested, and fully compliant with global quality standards.

Our relentless commitment to quality assurance positions AT&M as the trusted partner for Australian businesses across diverse industries, delivering PCB assemblies that consistently exceed expectations and drive business success.