The Power of Prototyping in PCB Assembly: Speeding Up Innovation

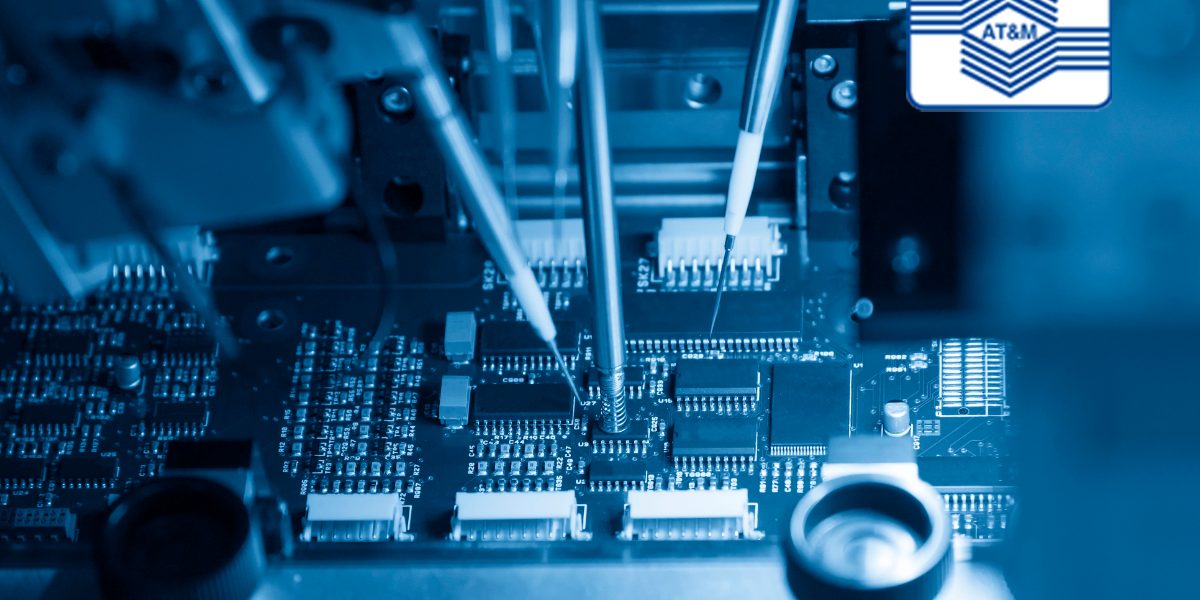

Prototyping is a critical phase in printed circuit board (PCB) assembly, acting as a bridge between design and full-scale manufacturing. In Australia’s rapidly evolving electronics industry, prototyping accelerates innovation, reduces risk, and improves product quality. At AT&M, we recognize the immense value of rapid and effective PCB prototyping, providing tailored prototyping solutions that empower Australian businesses to innovate quickly, effectively, and confidently.

What is PCB Prototyping?

PCB prototyping involves creating early, functional versions of printed circuit boards to validate designs, test performance, and identify potential issues before entering mass production. Prototyping allows engineers to refine electronic designs efficiently, significantly reducing product development cycles and associated costs.

The Importance of PCB Prototyping in Electronics Manufacturing

Rapid innovation and shorter time-to-market are key competitive advantages in today’s electronics industry. Prototyping enables designers to iterate quickly, enhancing product functionality and reliability, while ensuring cost-effective manufacturing.

Key Benefits of PCB Prototyping:

- Identifies and resolves design issues early

- Validates product functionality and performance

- Reduces costly design errors and production delays

- Shortens overall product development timelines

- Facilitates better communication between engineers, manufacturers, and stakeholders

Stages of PCB Prototyping

1. Initial Design and Conceptualization

Prototyping begins with clearly defined design goals, component selection, and preliminary schematic drawings. This stage helps visualize the product concept and ensures alignment with end-user requirements.

2. PCB Layout and Design Validation

Using computer-aided design (CAD) software, detailed PCB layouts are developed. Engineers meticulously validate designs against technical specifications, industry standards, and manufacturing requirements, minimizing errors before physical prototyping begins.

3. Manufacturing the Prototype

The next phase involves physically producing the prototype board. Advanced manufacturing techniques like rapid PCB fabrication and assembly enable quick turnaround times, critical for iterative prototyping cycles.

4. Testing and Iteration

Once assembled, the PCB prototype undergoes rigorous testing to assess functionality, performance, and reliability. Any detected issues are documented, analyzed, and rectified in subsequent design iterations.

5. Final Approval and Transition to Production

After successful testing and validation, the prototype receives final approval, signaling readiness for full-scale manufacturing.

Explore AT&M’s PCB Prototyping Capabilities

Prototyping Techniques: Rapid, Iterative, and Functional

Several prototyping methods are available, each serving unique purposes within the design cycle:

- Rapid Prototyping: Quickly creates PCB models for basic design validation.

- Iterative Prototyping: Involves multiple prototypes, continually refining and improving designs.

- Functional Prototyping: Fully operational prototypes closely resembling final production boards, suitable for comprehensive performance testing.

AT&M offers these prototyping solutions, tailored to customer needs, project complexity, and industry requirements.

Discover AT&M’s Rapid Prototyping Solutions

Applications of PCB Prototyping Across Industries

Prototyping benefits numerous sectors significantly:

- Consumer Electronics: Accelerates development of innovative gadgets and wearable technologies.

- Medical Devices: Ensures precision, safety, and regulatory compliance through rigorous testing.

- Automotive: Facilitates rapid development and validation of automotive electronics and safety-critical systems.

- Aerospace and Defence: Critical for validating reliability and performance under extreme environmental conditions.

- Industrial and Mining Equipment: Enables testing and refinement of rugged electronic components for harsh environments.

Prototyping for Enhanced Quality and Reliability

PCB prototyping directly contributes to improved product reliability and performance. By identifying and addressing issues early, prototyping reduces risk, improves product robustness, and ensures higher satisfaction for end-users. AT&M’s comprehensive testing capabilities, including functional testing, guarantee prototypes reliably reflect real-world operating conditions.

Reducing Costs and Time-to-Market

Prototyping significantly reduces overall development costs by catching design errors early. The iterative nature of prototyping avoids expensive